-

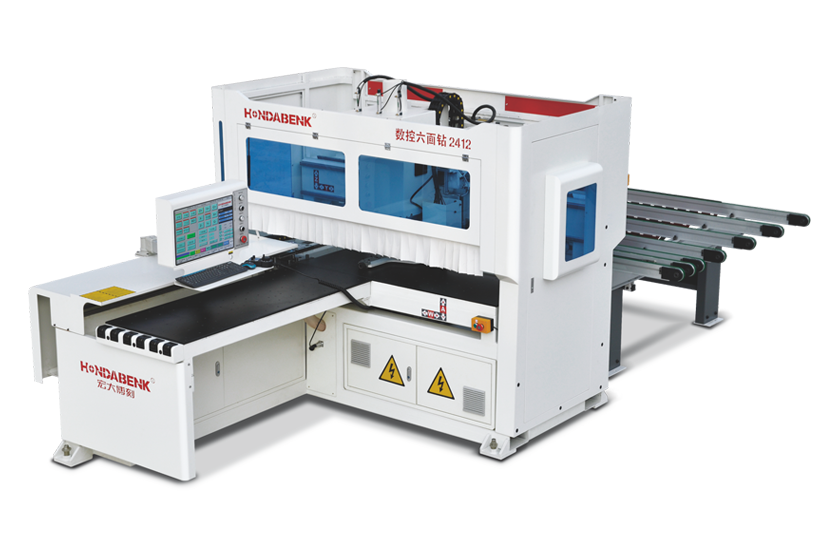

- Manual

- No professional Automatic loading and unloading General workers can operate

-

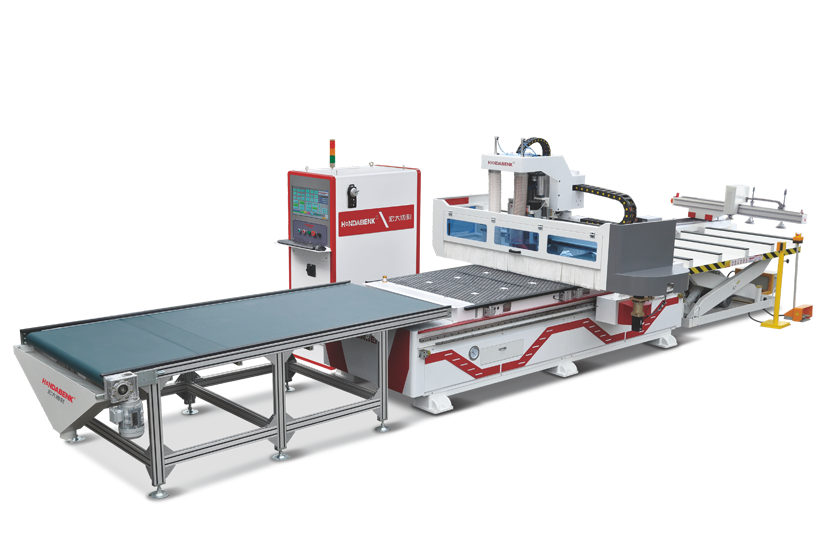

- Manual

- No professional Automatic loading and unloading General workers can operate

-

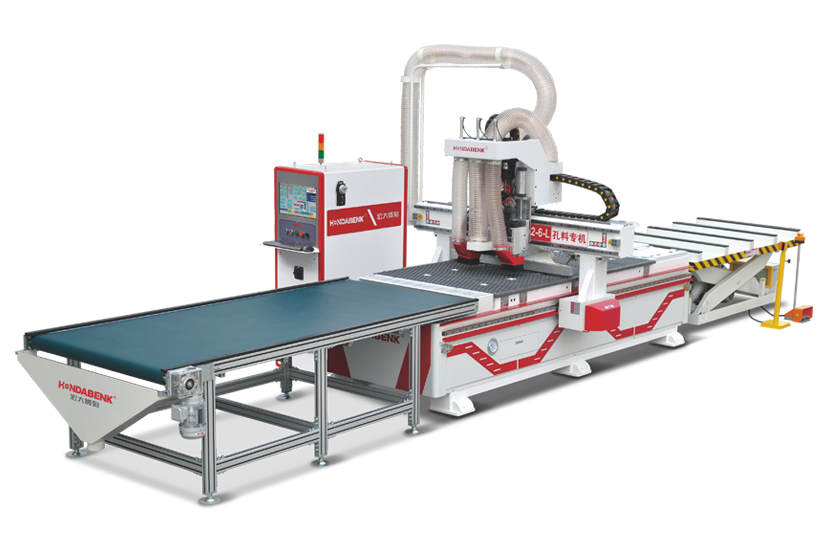

- Manual

- No professional Automatic loading and unloading General workers can operate

-

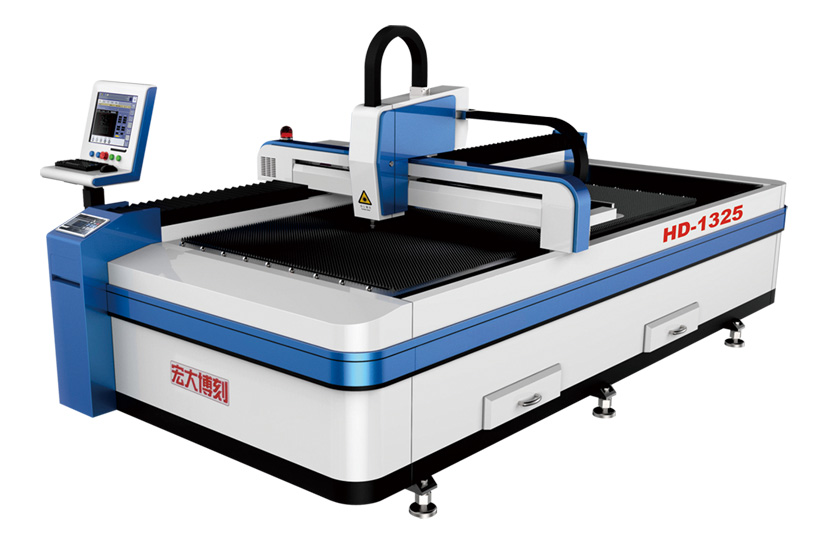

- Manual

- No professional Automatic loading and unloading General workers can operate

-

CNC opening system Cutting the preferred

Research and development for customized panel furniture

Seven advantages over traditional models -

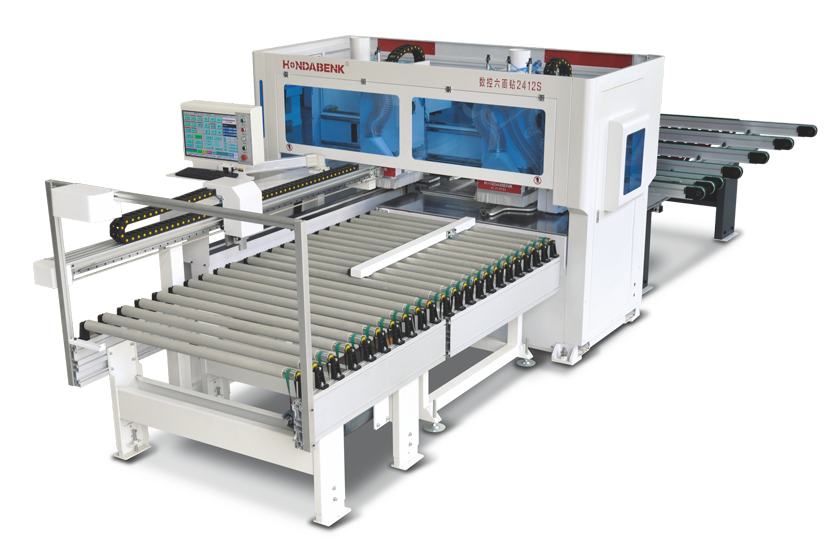

High precision

Zero error

The sheet material can be directly edge sealing

Don't need to rework -

System professional

Built-in optimization system

Automatic counting and discharging

-

High efficiency

8 hours a day

Guarantee the processing of 60 plates -

Put an end to inductrial injury

The man-machine separation

No work injury -

Profile forming

Profiled primary cut

No need for additional processing -

Save material

High utilization

Each plate can be used up to 2.7 to 2.8 square meters -

Manual

No professional

Automatic loading and unloading

General workers can operate

CNC material opening machine

CNC material opening machine